Energy consumption in drying processes continues to rise, while hot and humid exhaust air leads to significant heat loss, high humidity in workshops, and accelerated equipment corrosion. Our integrated “Dehumidification + Heat Recovery Solution” is designed specifically for drying applications in wood, food, grain, textiles, pharmaceuticals, feed, tobacco, sludge, and other industries. It delivers lower energy consumption, higher drying efficiency, and longer equipment lifespan.

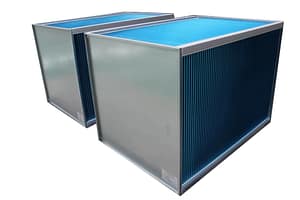

The system combines a condensation dehumidification module with a BXB air-to-air plate heat recovery exchanger. The exhaust air first passes through the condensation unit to remove moisture and corrosive condensates. It then enters the plate heat exchanger, where the remaining sensible heat is efficiently recovered and used to preheat fresh air or process return air. All air streams remain completely separated, ensuring no cross-contamination. The design works reliably even with exhaust containing steam, dust, or oil mist.

This combined approach reduces exhaust humidity by twenty to sixty percent and increases heat recovery efficiency by fifteen to forty-five percent. Drying energy consumption is significantly reduced, operating costs decrease, and the workshop environment becomes cleaner while equipment durability improves.

This is a forward-looking, high-efficiency, energy-saving drying solution that maximizes the value of every unit of energy and helps industries move toward greener, low-carbon production.